Single Worm Gear

Reducers

|

| Model |

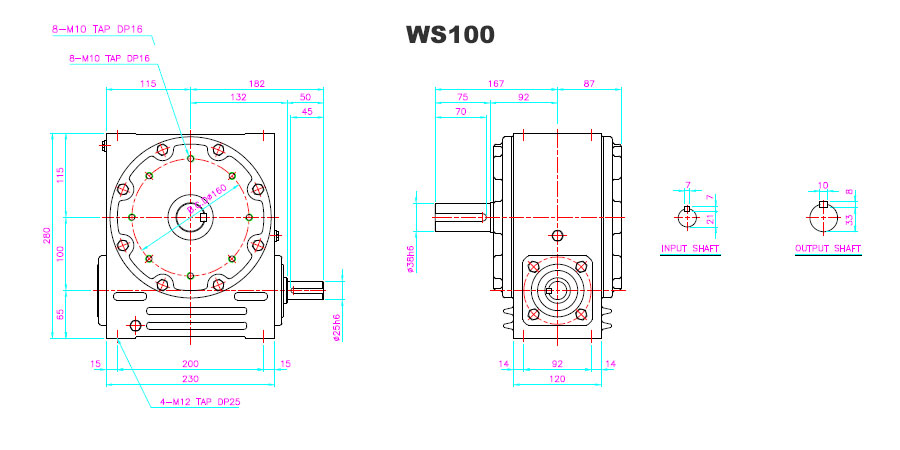

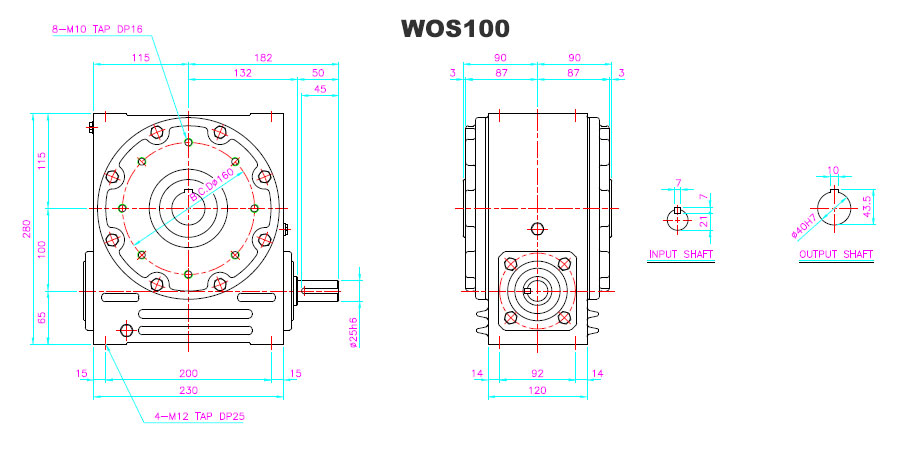

Gear Reducer: WS, WOS,

Geared Motor: WMS, WOMS |

| Ratio |

1/10, 1/15, 1/20, 1/30, 1/40, 1/50, 1/60 |

Reducer

(Worm) Size (mm)

(Distance between Input & Output Shaft Center) |

50, 60, 70, 80, 100, 120, 135, 155, 175, 200, 225, 250 |

|

Double Worm Gear Reducers

|

| Model |

Gear Reducer: WW, WOW,

Geared Motor: WMW, WOMW |

| Ratio |

1/200, 1/300, 1/400, 1/500, 1/600, 1/800, 1/900 |

Input

Reducer (Worm) Size (mm)

(Distance between Input & Output Shaft Center) |

50, 60, 70, 80, 100, 120, 135, 155, 175 |

Output

Reducer (Worm) Size (mm)

(Distance between Input & Output Shaft Center) |

80, 100, 120, 135, 155, 175, 200, 225, 250 |

|

2-Stage Helical-Worm Gear Reducers

|

| Model |

Gear Reducer: WH, WOH,

Geared Motor: WMH, WOMH |

| Ratio |

1/20, 1/30, 1/40, 1/50, 1/60, 1/80, 1/90, 1/100, 1/120, 1/150, 1/180 |

Input

Reducer (Helical) Size (mm)

(Distance between Input & Output Shaft Center) |

40, 50, 60, 70, 75, 80, 100, 125, 140, 155 |

Output

Reducer (Worm) Size (mm)

(Distance between Input & Output Shaft Center) |

70, 80, 100, 120, 135, 155, 175, 200, 225, 250 |

|

3-Stage Helical-Worm-Worm Gear

Reducers

|

| Model |

Gear Reducer: WWH, WOWH,

Geared Motor: WMWH, WOMWH |

| Ratio |

1/1000, 1/1200, 1/1500, 1/1800, 1/2400, 1/2700 |

Input

Reducer (Helical) Size (mm)

(Distance between Input & Output Shaft Center) |

40, 50, 60, 70, 75, 80, 100 |

Intermediate

Reducer (Worm) Size (mm)

(Distance between Input & Output Shaft Center) |

70, 80, 100, 120, 135, 155, 175 |

Output

Reducer (Worm) Size (mm)

(Distance between Input & Output Shaft Center) |

120, 135, 155, 175, 200, 225, 250 |

|

Special Ratio Gear Reducers

|

| Single

Worm Gear Reducer |

1/8, 1/25, 1/45, 1/75, 1/90 |

| Double

Worm Gear Reducer |

1/100, 1/150, 1/1000, 1/1200, 1/1500, 1/1800, 1/2000, 1/2500, 1/3000,

1/3600 |

| 2-Stage

Helical-Worm Gear Reducer |

1/25, 1/45, 1/70, 1/110, 1/130, 1/160, 1/170, 1/190 |

| 3-Stage

Helical-Worm-Worm Gear Reducer |

1/3000, 1/4000, 1/5000, 1/6000, 1/8000, 1/10000, 1/12000 |

|

|

Features

It guarantees reliability

and durability based on high-quality materials, reorganized standardization,

uniform parts and high-precision machining.

Compact Size and Light

Weight

Application of modular system and scientific calculation

minimizes the external size and weight of the main structure and

standardized components are used for assembly. In particular, the

upper and lower footrests are separated from the case so that they

can be used only when necessary.

Convenient Mounting

Since

the motor, reducer and driven machine are integrated in the hollow

shaft type, gear coupling is not necessary for the input shaft or

output shaft coupling. Worm speed reducer in hollow shaft can guarantee

easy installation and related machine life through good alignment.

The reorganized design enables universal installation. Flange, footrest

for installation, torque arm, power lock, etc. can be installed

in various ways.

High Efficiency and Precision

With

over 30 years of accumulated technical theory and production experience,

we are making precision gear reducer with pre-programmed maintenance

for the latest equipments, comprehensive management for workers

and thorough inspection of materials. Case, flange, cover and footrest

for the reducer main body are made of cast iron (FC20). Worm shaft

is high frequency heat treated after tempering and threaded parts

are polished for high efficiency and long life. Worm wheel is made

by casting AlBC2 or PBC2 on cast boss. Oil-bath lubrication is based

on synthetic oil and forced lubrication is also possible upon request.

The exterior and interior paint is adaptable to the general industrial

environment and has lacquer paint applied for additional painting.

|